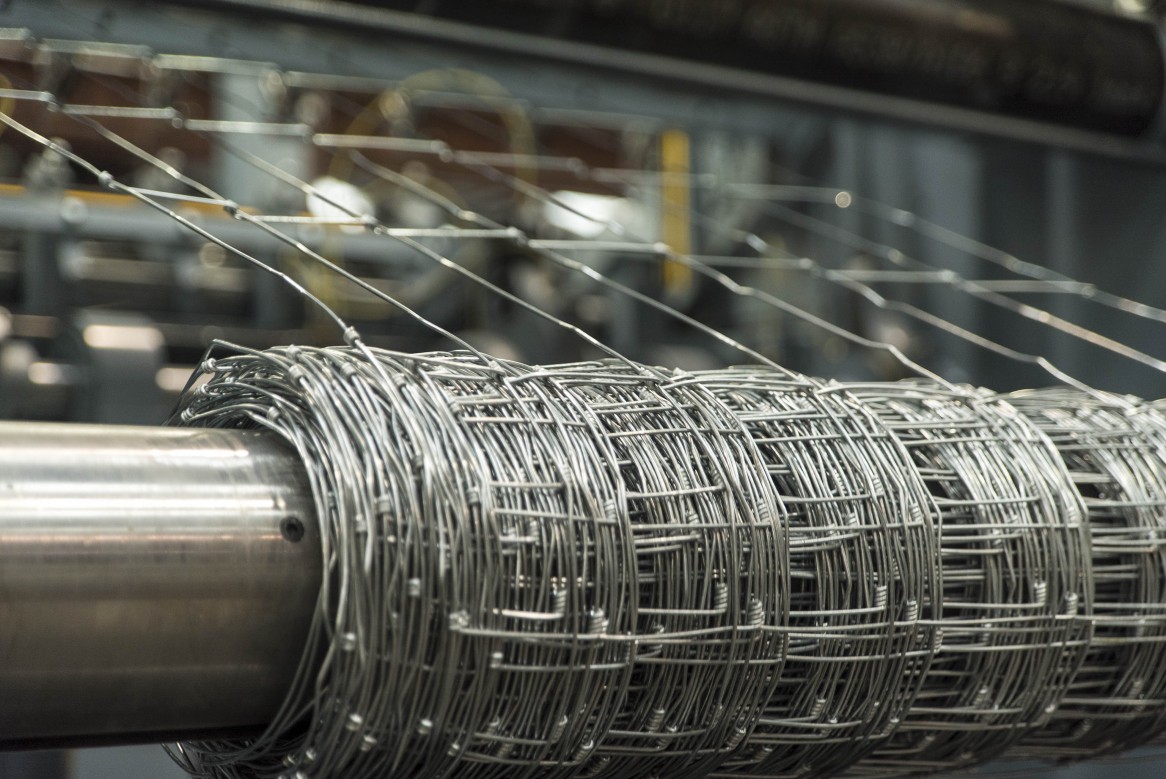

Hinge Joint Machine

The South Fence Machinery Hinge Joint machines have been developed from the company’s extensive experience of more than 85 years in the manufacture of wire fence products and wire fence manufacturing machinery.

The Hinge Joint was one of the first woven wire fence types to enter the market in the late 1800’s and is still used worldwide as a cost-effective fence solution. It consists of hinged joints that allow for fence flexibility at all points.

The Hinge Joint machine has played a vital role in the company’s success, which includes advancing hinge joint fence to a leading position in the New Zealand market and pioneering worldwide production of high tensile farm fences.

Learn more about the product and machine below, contact our team for quotes and further information.

-

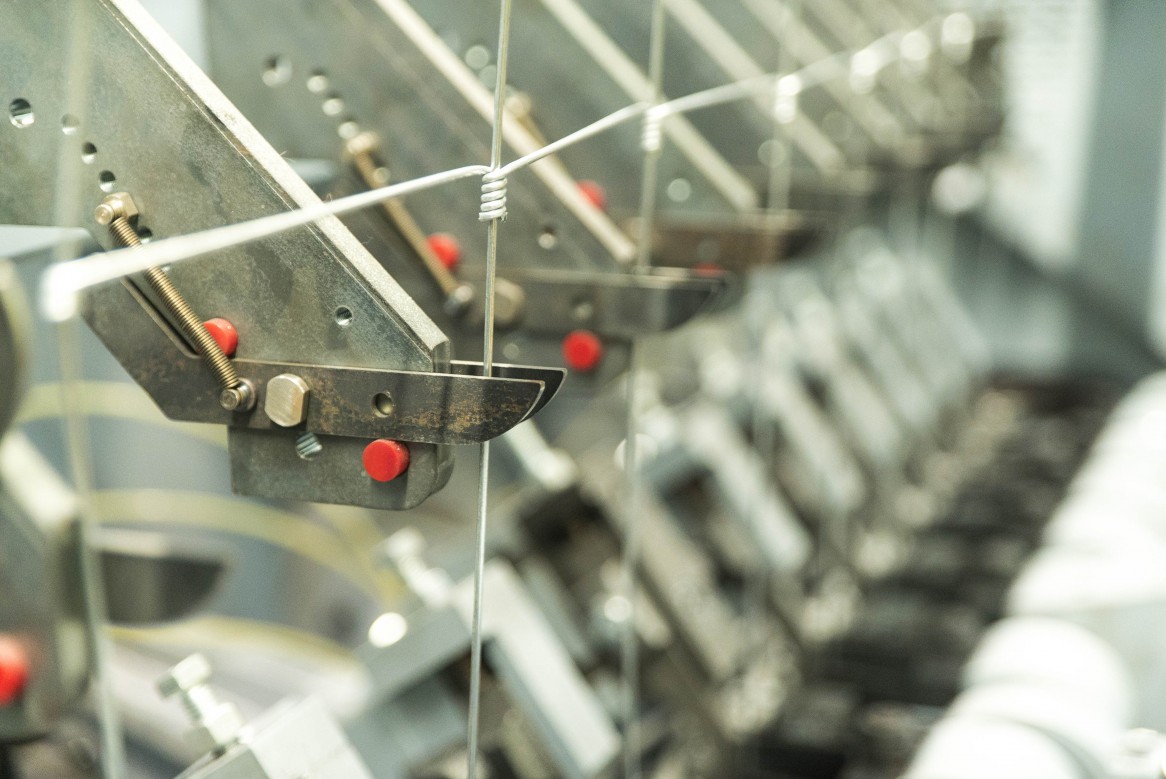

The fence is inherently flexible in nature due to the hinged wrap utilised, allowing for sections of the fence to be hinged to suit differing applications.

-

The fence wire’s tensile and wire gauge can be mixed and matched to suit market expectations.

-

Alternating Line-wire tension crimp ensures balanced tensioning of the fence during straining as well as temperature and terrain variation.

-

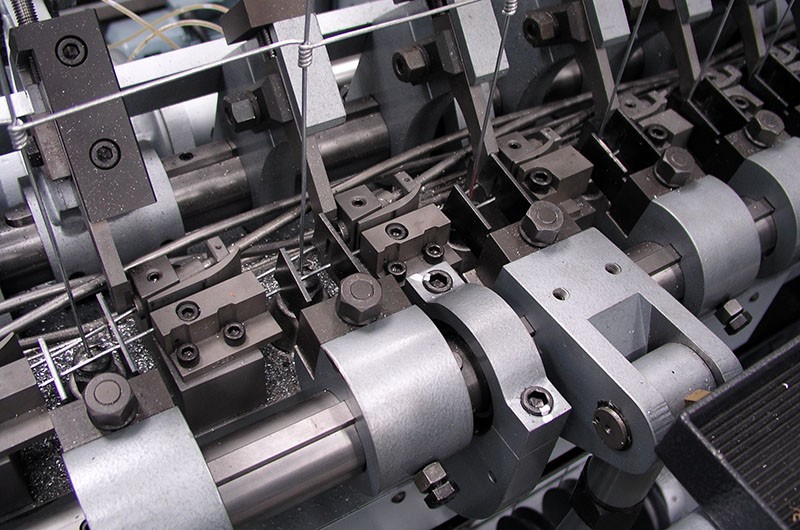

The method of twisting the hinge joint knot ensures a smooth wrap by rounding the hinge edges.

Our Hinge Joint fencing machines support all the features and functionality expected on any modern manufacturing machine:

-

Simple and well-engineered components ensure the machine runs reliably. If desired, the machine can be designed to support custom wire specifications.

-

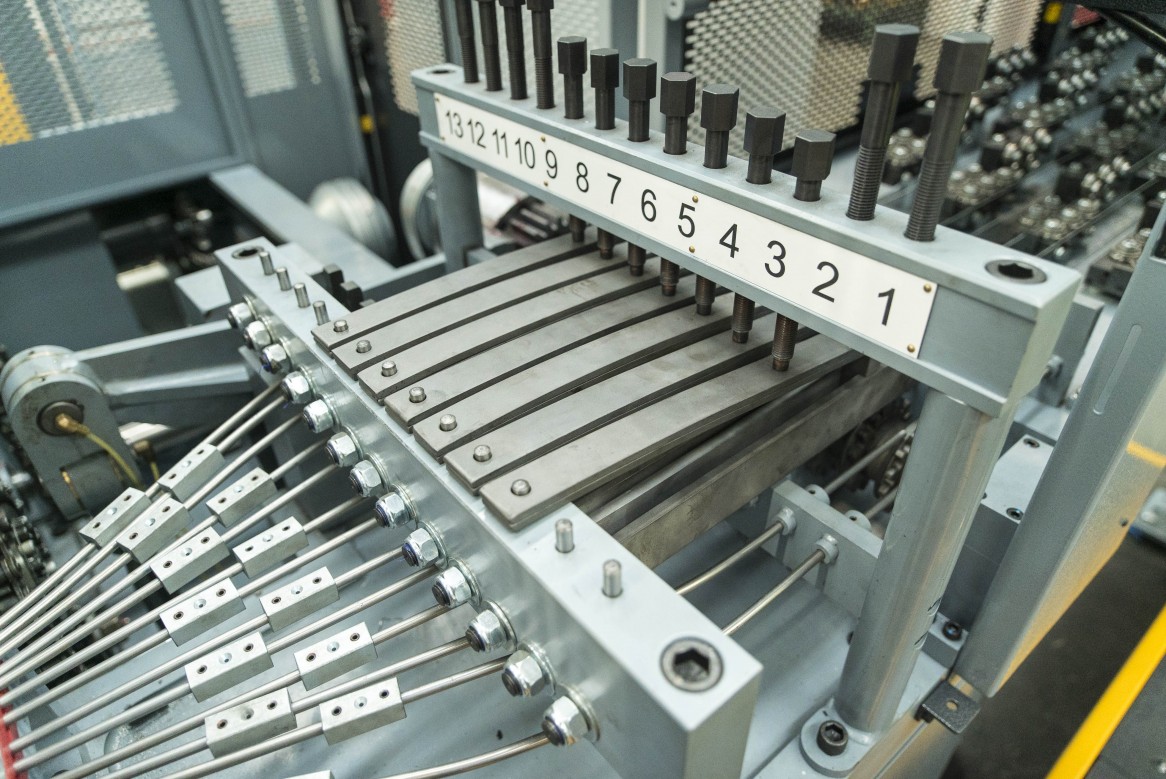

A range of crimping drum change gears along with simple mechanical adjustments ensures the machine operator can change and manufacture many common stay-wire spacing sizes.

-

The machine has a comprehensive arrangement of electric trip systems to ensure the machine stops in the event of wire tangle, breakage, or incorrect machine function.

-

The take-up assembly incorporates a driven stripper trolley and support trolley for easy roll removal to minimise operator fatigue.

All machines are backed by South Fence Machinery’s comprehensive warranty and after sales support to ensure your peace of mind.

The Hinge Joint machine has a full complement of safety systems to ensure your operator's safety. A full and comprehensive risk assessment is conducted on all South Fence machines in line with international safety regulations and CE compliancy.

Machine Safety Features:

-

Monitored Light Curtains on both the front and rear of the machine

-

Monitored RFID Interlock switches on all removable guards and doors

-

Siemens safety PLC to monitor all safety related control features

-

2mm punch panel guard system finished in a durable powder coat

-

Festo pneumatic safety valves and regulators

-

Comprehensive machine warning signage

-

Non-slip operator platforms with hand rails and kick boards

-

HMI operator fault banner system

-

Safe speed monitoring of all axes for machine set-up and fault finding

Compliance Standards:

|

ISO 12100:2010 |

General Principles for Design – Risk assessment and reduction |

|

ISO 13857:2008 |

Safety Distance to prevent hazard zones being reached by upper and lower limbs |

|

ISO 13855:2010 |

Positioning of safeguards with respect to the approach speed of parts of the human body |

|

ISO 13850:2015 |

Emergency stop function – Principles of Design |

|

ISO 13849-1:2015 |

Safety-related parts of control systems – General principles for design |

|

ISO 13849-2:2012 |

Safety-related parts of control systems - Validation |

|

EN 60204-1:2006 + A1:2009 |

Electrical equipment of machines – General requirements |

|

EN 62061:2015 |

Safety of machinery - Functional safety of electrical, electronic and programmable electronic control systems |

|

AS 4024.1-2014 |

Safety of Machinery |

|

AS 1657-2013 |

Fixed platforms, walkways, stairways and ladders – Design, construction and installation |

|

AS 1554.3:2014 |

Structural steel welding – Welding of reinforcing steel |

HJM 14L-Standard Wide Bed |

|

| Maximum Fence Height | 2 metres (79")* |

| Maximum Number of Horizontal Wires | 14 Line* |

| Vertical Wire Spacing | 150mm (6") and 300mm (12") Custom spacing available on request |

| Horizontal Wire Diameter | Top and Bottom Wires: Up to 3.5mm (0.140")Ø* Intermediate: Up to 2.80mm (0.110")Ø* |

| Vertical Wire Diameter | Up to 2.80mm (0.110")Ø* |

| Maximum Machine Speed | Up to 130 cycles per minute |

| Maximum Roll Diameter | 625mm (24.5")* |

| Safety Equipment Utilised | Fixed Guards CAT4 RFID Monitored Guards CAT4 Light Curtains |

| Dual Roll System | Available on request |

| Automatic Label Inserters | Available on request |

| Automatic Cut, Strip, & Reload | Available on request |

| Interrupted Stay Spacing | Available on request |

| Compensator Take-up | Available on request |

| Motion System | Controlled Siemens Servo Control |

| Automatic Lubrication System | Automatic machine and twister lubrication, additional lubrication options available on request |

| Approximate Floor Area Required | 10m x 9m (33ft x 30ft) |

* Variation to the specifications are available on request.

All weights and measures are approximate.

Machine

Machine Machine

Machine Machine

Machine